Integration and Assembly Activities

"Integration is not just putting together parts, but starting from an idea, constructing an idea into a product/system and perfecting techniques, carrying out final assembly and final testing so that it can be measured and perfected"

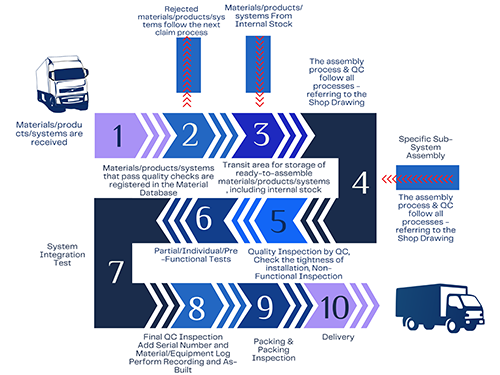

Simultaneously with the procurement process, the process of receiving materials/equipment/products/systems to be assembled is received at the warehouse according to the planned schedule. The process of receiving materials/equipment/products/systems, assembling, testing, packing, and shipping according to the flow as follows;

01

In the integration/assembly process, quality control is critical to ensure the assembled equipment/product meets project standards, avoids defects, and reduces rework before the assembled equipment is tested, packaged, and shipped to the client. The quality control process in process integration follows from the initial receipt of the goods until the goods are shipped.

02 - 03

Quality inspection, starting from the process of receiving materials/equipment/products/ systems. The materials/equipment/products/ systems that do not meet the standards set out in the project documents or are defective will be rejected and further processed by compiling a claim procedure and forwarded to the procurement/expediting team for follow-up. Furthermore, the appropriate ones are registered in the list of receipts of materials/equipment/products/ systems and warehousing for assembly purposes.

04

The assembling process is carried out after a quality check has been carried out and the goods/materials received have been registered on the stockiest/material list intended for assembling.

05

Physical quality inspection includes the tightness, installation accuracy, identification labels for each item/equipment and cable marking, inspection for paint defects, safety warning signs, and equipment numbers (tag numbers) according to project requests. The essence of this process is following the QC team's internal procedures and not functional testing

06

Furthermore, the device will be tested individually or tested for the function of each sub-system, if at this stage the device does not pass the test will be returned to the fifth stage for re-checking based on the record it has been created at this stage.

07

At this stage, all the equipment that passed the test in the previous stage will be tested as one system, which we call the "integration test". At this stage, it will be ensured that all system units are working properly and following project standards and requests. Furthermore, the equipment that passes the test will undergo a final physical inspection and be given a serial number which will then be forwarded for packing.

08

This final inspection focuses on physical inspection to ensure that all equipment that has been tested for integration has been installed perfectly without any defects, including the serial number of the equipment. Then it will be registered in the list of equipment to be sent (Packing List) and at the same time, all the documents needed for the shipping process will be prepared. Engineering drawing markup will be done and sent back to the engineering department for updating.

09 - 10

After going through all the steps above, the equipment will be packaged, before being sent a final check will be carried out on the results of the packing, including checking the destination address for delivery, completeness of safety sign, fragile and label requested by the project/contract for delivery purposes.